Learning Objectives/Experiments:

Distribution Station:

-

Function: Supply the work piece in stock bin in sequence, work piece in place, electrical cylinder put the waste into waste bin, put the qualified material block into punch station

Structural composition:

-

Aluminium basal plate, electric control cabinet, PLC hung box, Operation panel, Pneumatic cylinder, charging barrel, magnetic valves, Mini cylinder, vacuum chuck, parallel lines Groove, I/O switch over Module, Air controller.

Main electrical components:

-

Illuminated push button stop/start: LAY50-22D one open DC24V

-

Button signs: Φ22

-

Fibre optic sensor amplifiers: 6 bets

-

Fibre optic sensor Amplifiers: PNP DC24V

-

The receiver transmitter (generator): PNP DC24V

-

Dimension: Approx. (Length*width*height)- (460 x 800 x1270) mm

-

Learning Scope Distribution station:

-

Sensor Adjust Training

-

Air circuit connect training

-

PLC program Training

-

Distribution station control training.

Handling station:

-

Function: Qualified material block transmitted to feed opening port, electrical robot arm, put away the transmitted work piece, depth sensor detects it, unqualified parts be transmitted in waste groove, qualified parts will be transmitted to next station.

-

Structural composition: Aluminium Basal plate. Electric control cabinet, PLC hung box, Operation panel, Belt conveyor machine and install bracket, punching cylinder device and all the external member, parallel lines groove and guide Rail, I/O switch over module, Air source processor and Send receiver.

-

Main electrical element:

-

Fibre amplifier: PNP DC24V

-

Fibre cable: Electric Actuator

-

Dimension: Approx. (Length*width*height): (460 x 800 x 1050) mm

-

Air source pressure: 0.4~6Mpa

-

Learning Scope Handling station:

-

Sensor Adjust Training

-

Air circuit connect training

-

PLC program Training

-

Punching station control training

Assemble Station:

-

Function: Equip with TAG material block, distinguish colour and material of the material block by sensor test area, wait in barrier cylinder colour and material of cover distinguished by sensor on the 1# convey belt and 2# convey belt put on material block equipped with a TAG by extending cylinder and vacuum sucker.

-

Structural composition: Aluminium Basal plate, Electric control cabinet, PLC hung box, Operation panel, Electric unit install board, Vacuum generator sucker port, Vertical cylinder bracket and barrier block, Section for install and assemble, Air source processor, connect bracket between station and station, Solenoid valve, I/O switch over module, Belt conveyor install bracket and cover guiding arc module.

-

Main electrical element:

-

Inductive sensor: PNP or NPN, DC24V

-

Fibre amplifier: PNP DC24V

-

Signal generator: PNP DC24V

-

Intermediate relay (with handle): 2 open 2 close DC24V

-

PLC controller: suitable as per station

-

Switch power supply: 24V 5A

-

D type plug: AC220V 10A

-

Dimension: Approx. (Length*width*height) :(460 x 800 x 1160) mm

-

Learning Scope Assemble station:

-

Sensor Adjust Training

-

Air circuit connect training

-

PLC program Training

-

Assemble station control training

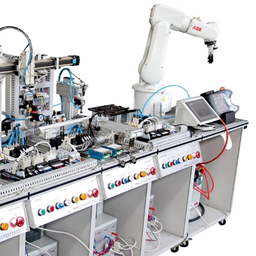

Industrial robot handling station and classified storage:

-

Function: Industrial robot according to different colour and material of processed material block to classified storage.

-

structural composition: Aluminium Basal plate, Electric control cabinet, PLC hung box, Operation panel, parallel lines groove and guide rail, I/O switch over module, Air source processor, Slope bracket and slope slide groove, Robot controller, Robot teaching units, Robot I/O extend plate, Solenoid valve, teach screen install plate.

-

Main electrical element:

-

Fibre sensor: BF3RX PNP DC24V

-

Fibre cable: E32-DC200-6FD

-

Signal generator: MBS5M-TDT1 PNP DC24V

-

Intermediate relay (with handle): 2 open 2close DC24V

-

Gray cable groove: 3030

-

Aluminium guide rail: DIN35mm

-

Touch screen: MCGS 7062k

-

D type plug: AC220V 10A

-

Training project: Industrial robot handling station control training, classified storage station control training, Touch screen and communication control training.

-

Dimension: Dimension: (Length*width*height): Approx.: 900mm*900mm*1110mm

-

Air source pressure: 0.4~0.6Mpa

Learning Scope Assemble station:

-

Sensor Adjust Training

-

Air circuit connect training

-

PLC program Training

-

Industrial Robot handling station control train

Features

-

Equipment Description: The device is focus on “Industry 4.0” development of vocational education, which is based on systematic job flow system solutions, it is comprehensive application reflect of “Internet +”,” industrial robot”, “Sensor”, “PLC control technology”, “smart electromechanical equipment “and other technology.

-

Therefore, it has also become World Skills “mechatronics,” required professional Equipment.

-

On automatic line always use sensor technology, electrical technology, and control technology, servo driven technology, just like human’s Sensory system, sport system, brain and nervous system.

-

Then use automatic line as vector to state above key technology.

-

Equipment working principle:

-

Work piece in stock bin supplied in sequence, once detected work piece in place, pneumatic swing cylinder put material block into second handling station.

-

Working process of handling station:

-

When work piece come from last station, actuator moves to the left slug crawling position, vertical cylinder down, down in place, the air fingers crawl, crawl.

-

into place → actuator moves to the right position → discharge gas release your finger → → wait for the next vertical cylinder rising feed, single station comprising qualified and unqualified silo, used as sorting material.

-

Working process of assembles station:

-

Tag containing billets, after detecting sensor distinguish the colour and texture of the material block, waiting at the cylinder block material, colour and texture through the lid # 1 transmission belt and transmission belt sensor 2 # tell the difference, after a stretch a cylinder and a vacuum chuck mounted on the Tag into billets by belt conveyor to the storage station.

-

Working process of handling and stacking station:

-

After gob handling over, according to the different colours and materials of processed material blocks to classification storage.

Specification/Technical data

-

Integrated source: 10 Road; integrated gas source: 4;

-

repeat positioning accuracy: 0.01mm;

-

degree of protection: IP30;

-

rotation axis working range + 165 ° ~ -165 °

-

Speed of 250 ° / s;

-

2-axis arm operating range +

-

110 ° ~ -110 ° speed of 250 ° / s;

-

3-axis arm for the range of + 70 ° ~ -90 °

-

Speed of 250 ° / s;

-

axis 4 wrist operating range + 160 ° ~ -160 °

-

Speed of 320 ° / s;

-

bending axis 5 working range of + 120 ° ~ -120 ° speed of 320 ° / s;

-

shaft 6 flip working range + 400 ° ~ -400 °

-

Speed 420 ° / s;

-

1 kg Picking beat: Approx. 25 × 300 × 25mm,

-

58TCP speed, 6.2m / sTCP acceleration of 28m / s,

-

acceleration time 0-1m/ s207s Supply Voltage: 200-600V, 50 / 60Hz;

-

Power: 0.25kW;

-

robot base size: Approx. 180 × 180mm;

-

height of the machine: 700mm;

-

robot weight: Approx. 25kg;

-

outside with Device Net module

-

Cabinet main circuit power supply: single-phase AC220V ± 10%, 50Hz

-

Robot Model IRB120 / 3KG / 0.58 or Equivalent

-

Cabinet control circuit power supply: DC24V

-

Temperature: -10 ℃~ 40℃; Humidity: ℃ ≤90% (25 ℃);

-

Single Station Dimensions standard table.

-

Air pressure: 0.4 ~ 0.6Mpa

-

Machine capacity: ≤5KVA

-

NOTE: COMPUTER NOT IN OUR SCOPE OF SUPPLY

Dimensions and weight