Learning Objectives/Experiments

Features

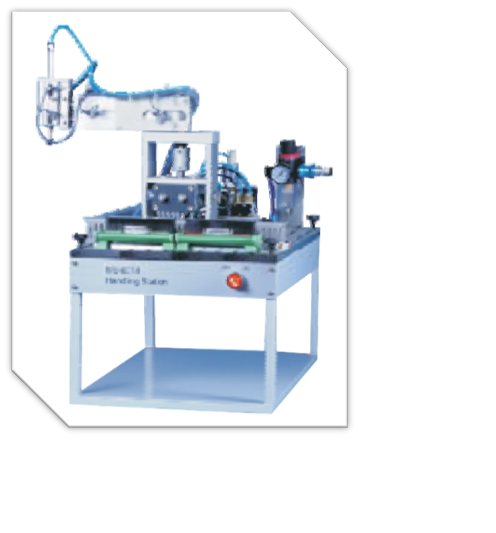

Modular and flexible

Specification/Technical data

Dimensions and weight

Office: S. N. 37/02, "Ashtavinayak Indl. Estate",

Parvati Nagar, Dhayari Narhe Road,

Next to Pari Robotics, Narhe, Pune-411041

Tel fax: (020) 24690312,

Email: sales@xeepl.com, xeepl.pune@gmail.com