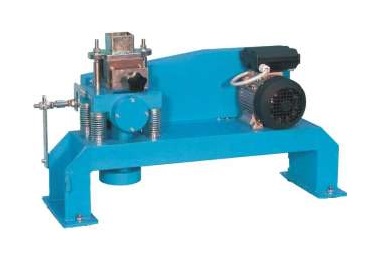

VIBRATING MACHINE:

(Also called MOULD VIBRATOR OR MORTAR CUBE VIBRATOR)

AS PER IS. 4031 - 1968 and 1344 - 1959, BS: 12.

Introduction: Concrete moulds are easily cast by using a tamping bar or a vibrating table. However air trapped in cement mortar paste cannot be thus removed while casting cement mortar moulds. Easy method is to impart greater vibration of lesser amplitude to the mould while casting. This is achieved in a Vibrating Machine. Vibrating Machine is used for the preparation of mortar cubes for the determination of compression strength of ordinary and rapid hardening Portland cement, low heat Portland cement, Portland bleast furnace cement and high alumina cements.

General Description and Specifications:

Spares: Set of Springs, Belt and Belt guard.

Office: S. N. 37/02, "Ashtavinayak Indl. Estate",

Parvati Nagar, Dhayari Narhe Road,

Next to Pari Robotics, Narhe, Pune-411041

Tel fax: (020) 24690312,

Email: sales@xeepl.com, xeepl.pune@gmail.com